Tread Carefully: The Manner in Which Tire Patterns Influence Your Semi-Truck's Efficiency

Regarding fleet managers and long-haul truck drivers, the decision of tires is crucial in ensuring optimal performance and safety on the road. Semi-truck tires are beyond rubber on wheels; they serve a key role in gas mileage, cargo capacity, and overall truck performance. With the wide range of options on the market, understanding how tread designs and types influence your rig's operational effectiveness is critical.

From selecting the appropriate tread for various climate scenarios to identifying the signs that it's right time for a new tires, every aspect of tire management contributes to the bottom line. In an environment where efficiency can mean the difference between profit and deficit, maximizing tire performance is essential. Exploring how tire selection affects fuel efficiency and learning maintenance best practices will enable drivers and fleet managers alike to perform effectively while getting the job done efficiently.

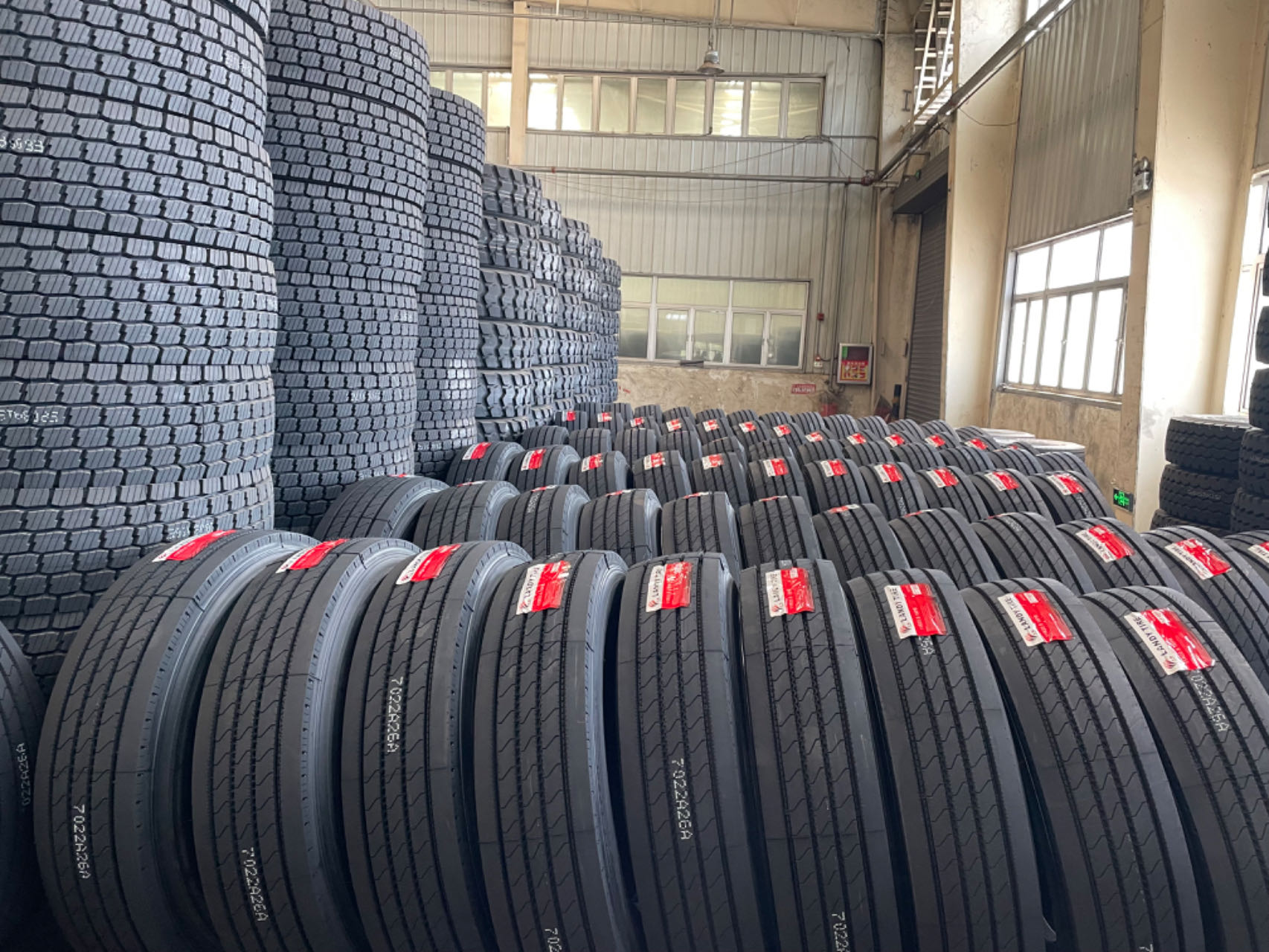

Choosing the Best Tires for Optimal Performance

Determining the best tyres for your semi-truck is essential for boosting efficiency and overall functionality. The tyre's tread design can greatly impact fuel consumption, maneuverability, and traction. It’s critical to consider the specific needs of your business, such as the kind of freight being transported and the roads regularly taken. For example, long-haul trips on interstates may require tires with a reduced rolling resistance to enhance fuel efficiency, while off-road or uneven routes require a more assertive tread design for superior traction.

An additional key aspect in choosing the best tyres involves comprehending the various styles available. Front tyres, designed for the front of the truck, offer superior control and handling, while drive tires, which are placed on the rear axles, focus on providing power and traction. Balancing these two types guarantees an efficient performance, as utilizing incompatible or inappropriate tyres can result in increased wear and reduced fuel efficiency. By investing the effort to align your tire choice with your operational needs, you can realize significant savings in both fuel expenses and tire lifespan.

Furthermore, maintaining tire pressure plays a crucial role in efficiency. Correctly inflated tyres lower friction, which can increase fuel efficiency and reduce wear. Regular checks and maintenance practices are essential, not just for tire pressure, but also for wheel alignment and balancing, which further contribute to the overall effectiveness of your semi-truck. By committing to the right tire choice and maintaining them effectively, you can guarantee optimal performance and durability, eventually impacting your profit margins positively.

Maintenance and Safety Optimal Practices

Regular maintenance of semi-truck tires is crucial for guaranteeing safety and extending their longevity. One key aspect is ensuring proper tire inflation, as low-pressure or high-pressure tires can lead to uneven wear, lowered fuel efficiency, and an heightened risk of tire failures. Fleet managers should invest in tire pressure monitoring systems to monitor tire inflation in real-time updates, allowing for immediate action if any issues are detected.

Another important practice is conducting regular inspections of tires prior to each trip. Drivers should look for signs of damage, such as breaks, protrusions, or debris lodged in the tread. Additionally, checking for 11r22.5 can help identify wheel alignment or suspension issues that may affect tire performance. Keeping a record of tire conditions and any repair work performed can also aid in tracking tire health over time.

Furthermore, correct tire rotation is crucial to ensuring even wear across all tires. Depending on the type of semi-truck and its usage, tires should typically be changed every 5,000 to 10,000 miles. This practice can help prolong the life of the tires and improve overall vehicle security. It's important for fleet managers and drivers to stay informed about best practices for maintenance and to adhere to manufacturer recommendations for tire care.

Grasping Tyre Tech and Developments

In the quickly developing landscape of heavy-duty truck tyres, technology plays a crucial role in boosting performance and safety. One major development is the emergence of intelligent tires featuring devices that observe tyre inflation, temperature, and overall health in real time. These developments enable fleet managers and operators to receive alerts about potential issues before they result in more severe complications, thus lowering downtime and boosting fuel efficiency. This change towards connectedness is transforming how fleets manage tire health and maintenance.

Another trend in the tyre industry is the focus on sustainable materials and designs. As environmentally-friendly practices becomes more crucial, companies are researching the use of sustainable resources in tire production and creating products that reduce drag. Decreased rolling resistance not only lowers gas consumption but also extends the lifespan of tyres, making them a prudent investment for extended operators. Eco-friendly tire selections cater to fleet managers trying to reduce their environmental impact and adhere to environmental regulations.

Additionally, improvements in tread design and rubber materials have caused better grip and durability for heavy-duty tires. Different tread patterns are now tailored for targeted purposes such as off-road transport or optimal on-road performance. This level of specialization enables vehicle drivers to choose tyres that are ideal for their unique freight and pathways, ultimately enhancing overall operational efficiency. As technology keeps to progress, semi-truck tires will likely include even more advancements that prioritize security, performance, and eco-friendliness.